hey there,

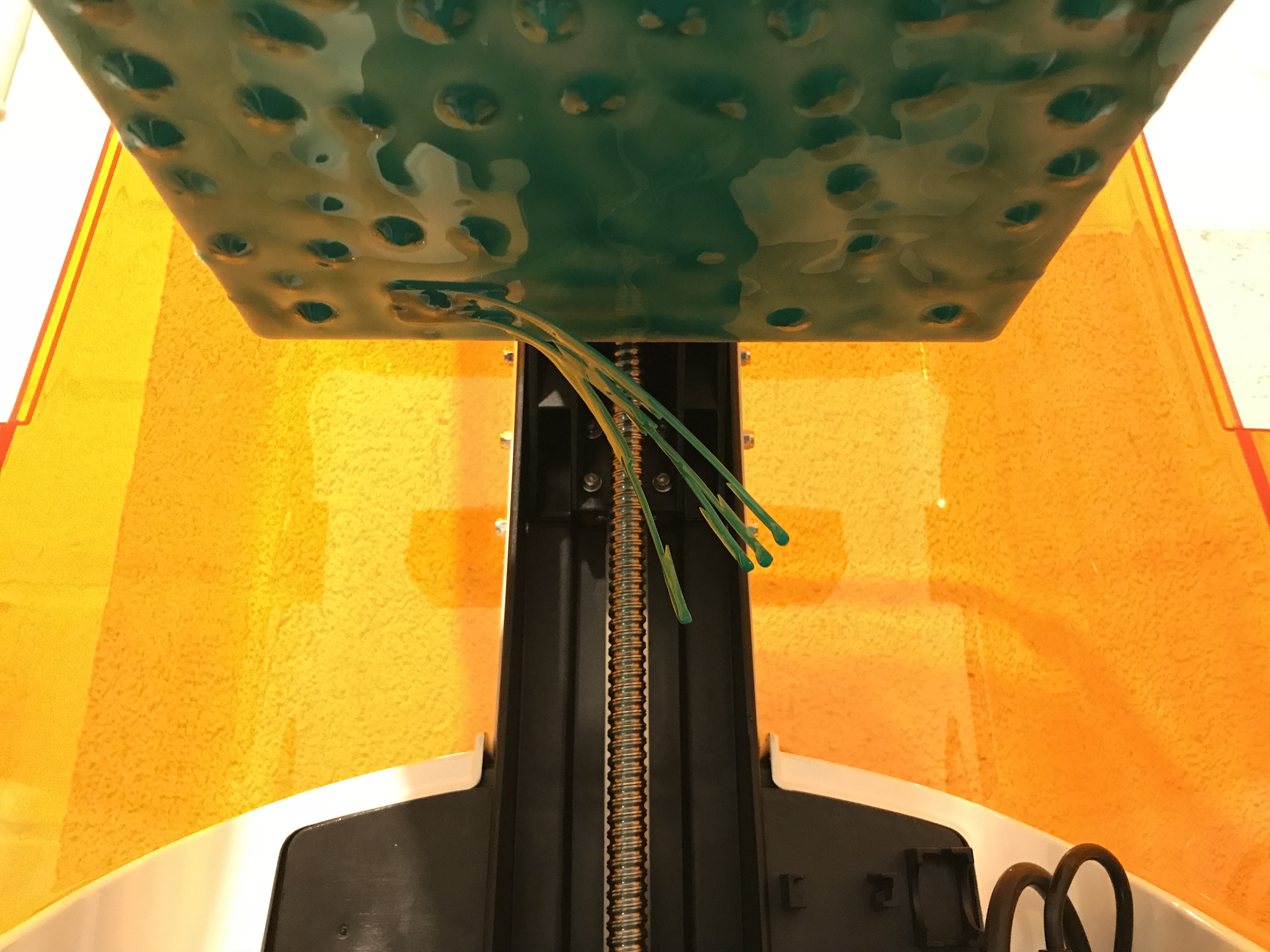

I tried to print Objects in varying sizes – meaning the area sticking on to the buildplatform varies from just supportstruckture up to two thirds of that area is covered by the actual build.

I tried to use clear zPMMA and performed the following tweaks.

I sanded the buildplate with P60 and later with P40.

Calibrated the z axis many times.

I made shure there is no misprint leftovers in the vat.

I read on this forum that the resin bottle should be shaken but not to much and just to be save I took it out and made shure it wasn´t shaken insuficiently.

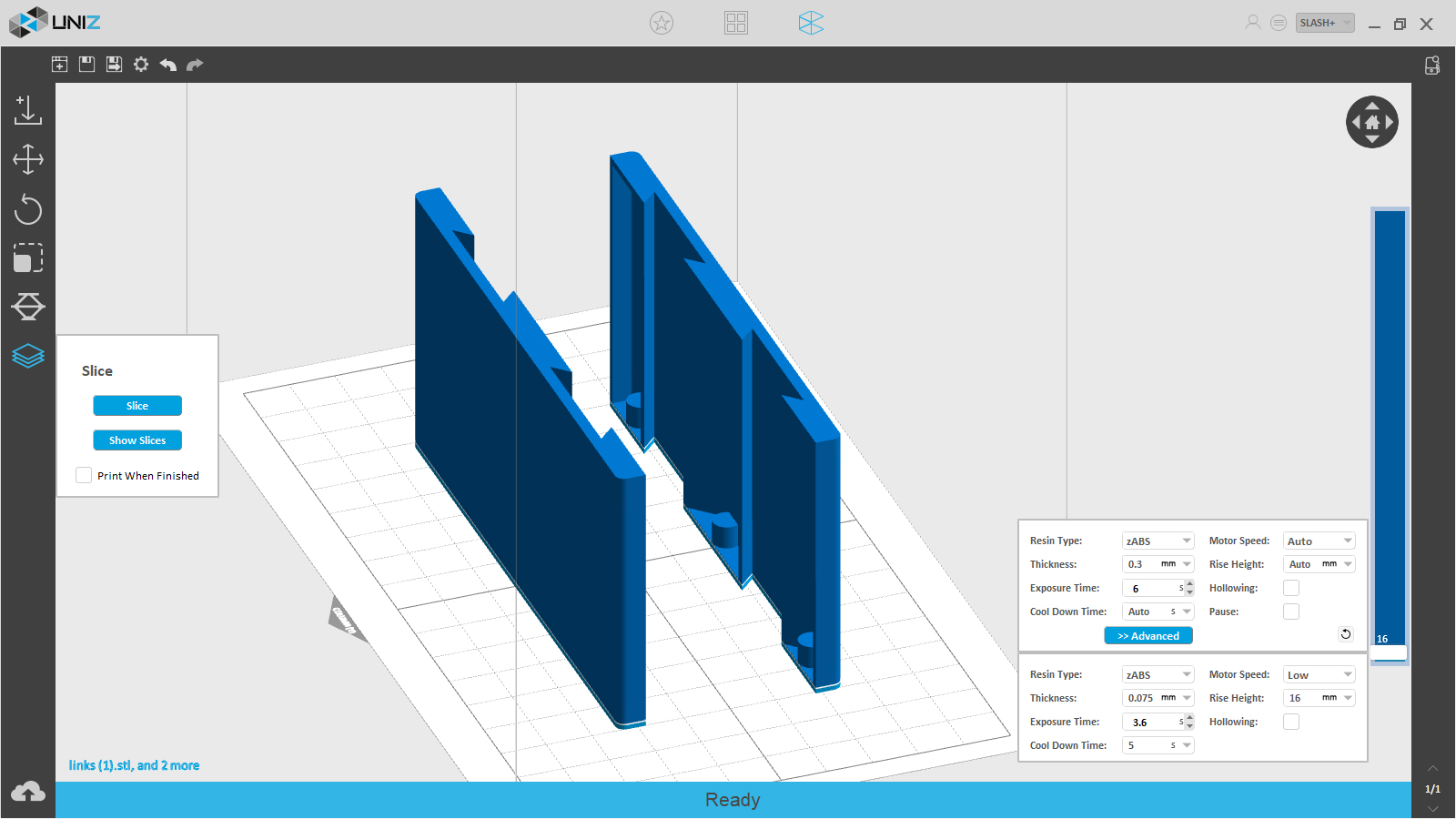

Most of the trick stuff can probably be done by adjusting the curing time. So I tried 0,05mm with 3 sec. to 10.sec for 15layers.

than 0,3mm with 6sec to 15 sec. curing with slow motor 16mm lift and pause…

I did many test series for 8h and wasted 250ml of resin, and now I ran out of ideas what could be done to make the build stickt to the Platform.

I still have a bottle of green resin. It came to my mind that there could be something wrong with the clear zPMMA. But if the solidifying component in the green and the clear stuff is the same there should be no differnence and I could even just continue with green resin without washing the entire resin system. Could I?

If anybody has some experience with the clear zPMMA or has overcome the severe -non stick- problem in general, please let me know.

Thanks in advance – Chris