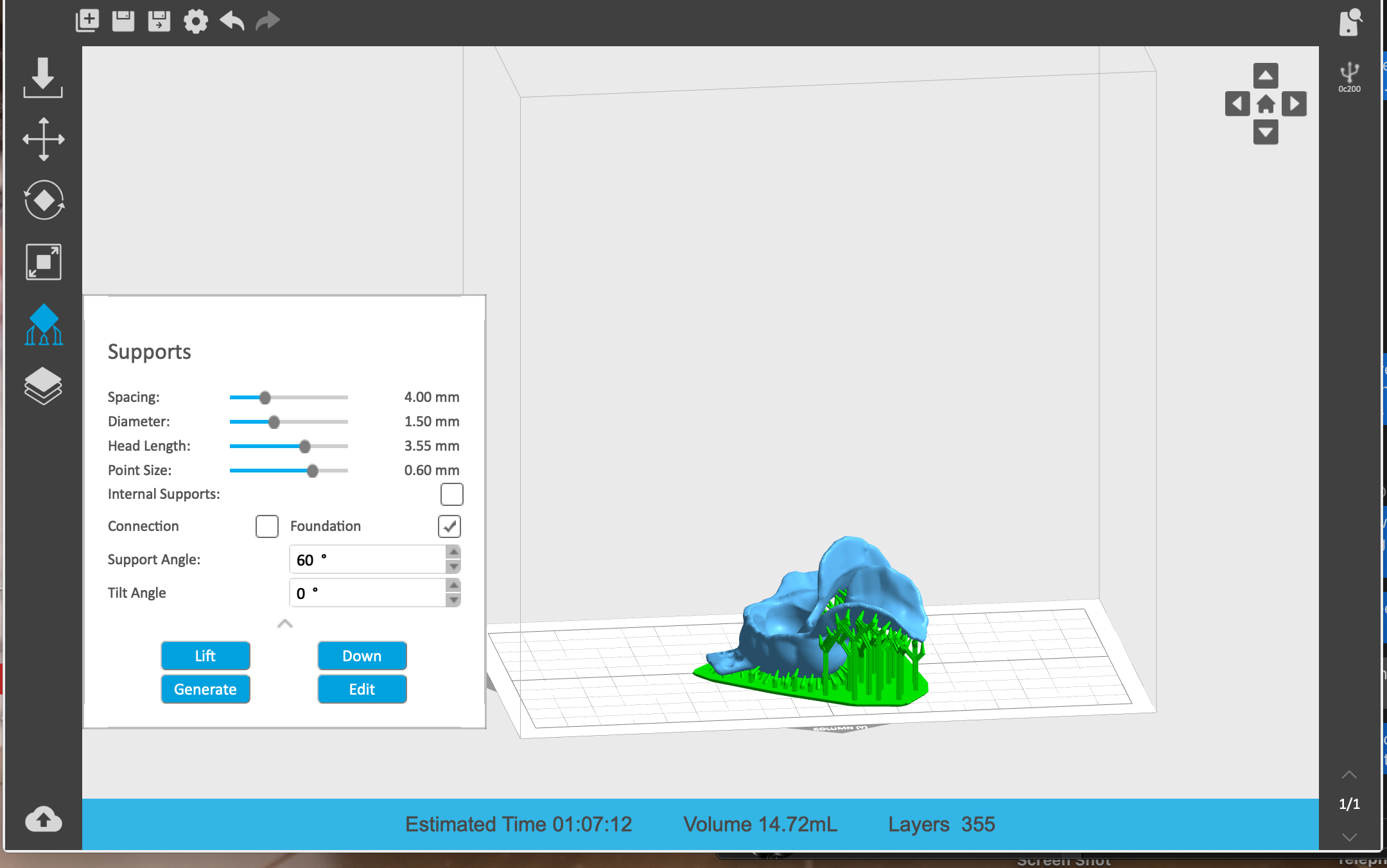

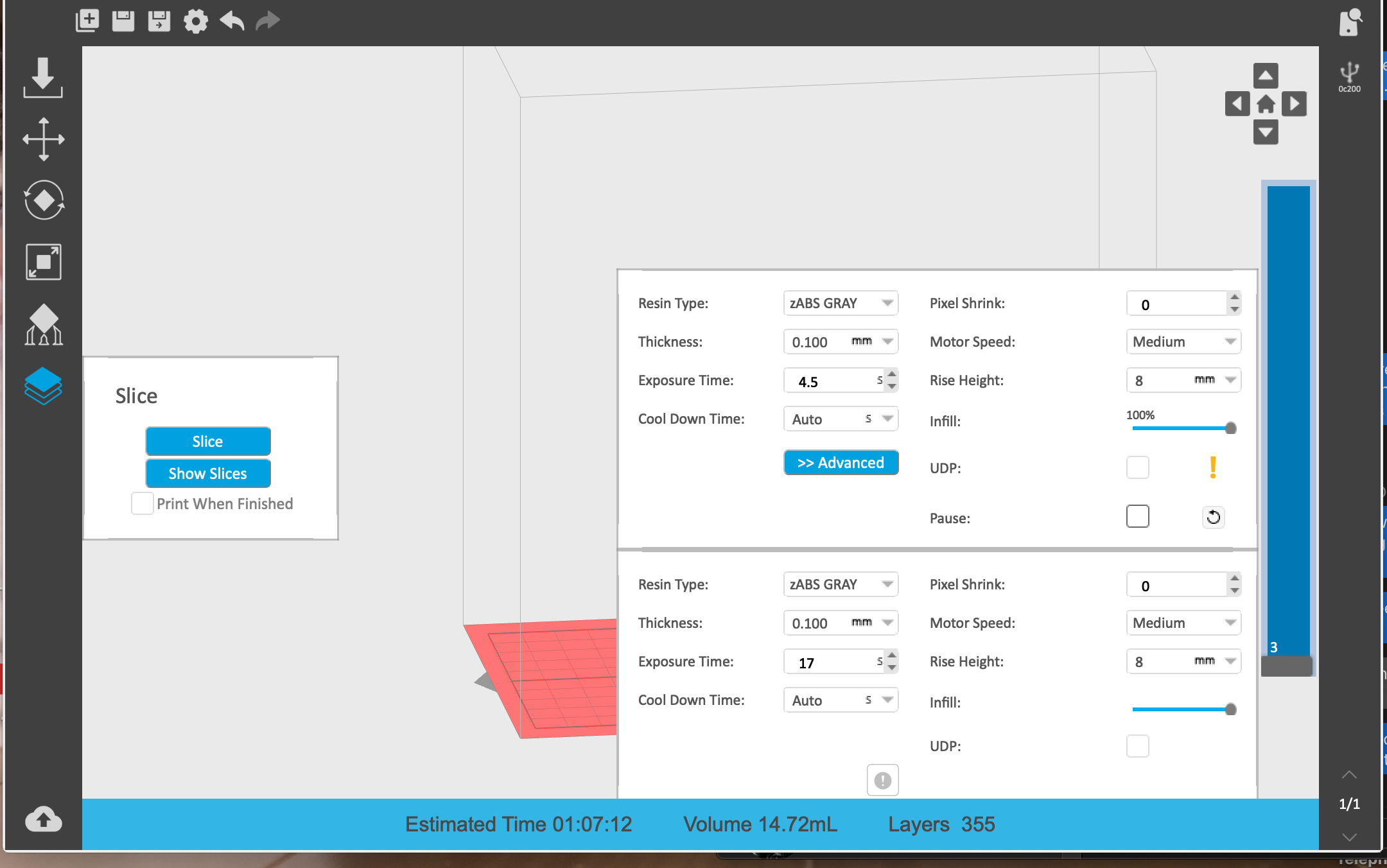

Well, I tried my first print and the only result was a few layers of material stuck to the screen. As this was the very first print, with a brand new screen, new, freshly opened resin, there is no way that “At the beginning of the printing, there is solid resin residue on the build platform surface that causes damage to the resin tank film” as mentioned in the troubleshooting section.

@Uniz, is there a fix for this? If not then I will expect you to send a new working resin tank to replace this one.