As I moved away my printer from my desk (for the terrific smell…), taking advantage of the new wifi/lan feature, I have some suggestions that would greatly improve the usability of the printer, hope you’ll evaluate them.

- [BUG] This is the most annoying, actually. Seems a firmware bug. Wifi connection is working great, but it happens often that the printer stop to be visible from the software (even pressing the scan network printers button doesn’t detect it anymore). The strange this is that from “My printers” on your site the printer is online and I can take a picture. This issue disappears only by power cycling the printer. Very bad as it happens at random moments, nearly every time during a print, so I stop to receive status updates.

- [SUGGESTION] As with wifi/lan function the printers will be positioned away from users desk (due to the very bad smell!), the operations to z calibrate, fill resin, redraw resin, etc are very unconfortable as you’ll have to run from PC to printer, from printer to PC, and so on. My suggestion is to use the slash front button to confirm/cancel the operation that you launched from PC. Example: fill resin. Press fill resin on PC and do it until you repress the same button on PC (like it’s not) OR you press the front button on the printer. This is particolarly useful for safety too (see next point). In this way you’ll not have to run from PC to printer…

- [SUGGESTION] Uniz resin bottles should be little bigger (in height, to be compatible) with some air inside, to be able to contain the resin that could normally be in the VAT. IT happened to me that I had to change the bottle. Then, after the print completed, I had to redraw the resin to clean the VAT. But after some time (I was near the printer, away from PC) the resin began to spill from the upper hole in the bottle! Complete panic as I could not do anything there! So I ran again to the PC, that in the meanwhile was locked, inserted my password (while the resin was spilling from the top of the bottle) and finally I could stop the operation. Think if in the meanwhile the connection was interrupted as it happens now…

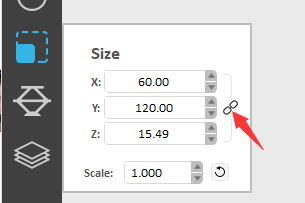

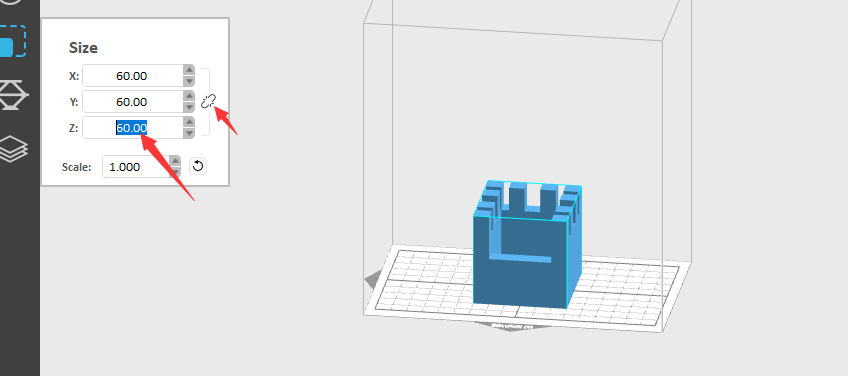

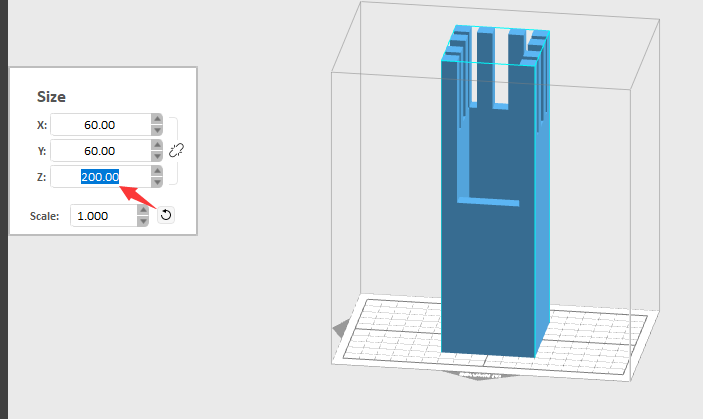

Yes, I could power off the printer.. But I didn’t think it in the hurry. However, if in the bottle there is some spare space that would be possible without problems. Maybe you want not do it due to oxidation, I don’t know, but that’s an idea. - [SUGGESTION] Please in the software insert a move / scale / rotation toggle snap (mostly rotation). Take as an example Autodesk Meshmixer to understand what I meaning.

- [SUGGESTION] Insert the webcam watching live from the Uniz software, possibly not passing from the cloud, that would be extremely useful with printers away from PC (as I suspect everyone will have)

- [SUGGESTION] Make the webcam and remote monitoring of the printer a standalone function that the printer expose locally on her own IP, not only via the cloud. In this way we can, with a simple NAT on the router, access directly the printer from the web. And the same from the local LAN. This mostly because of the next point…

- [SUGGESTION] Accessing the printer monitor from your site is very slow, at least from Italy. I don’t know if the bottleneck is your cloud performance or the bandwidth between Europe and America. In the last case maybe you can consider replicating the site in a Europe server farm (using Azure, for example, you can select where you want to host in the world…) As passing through the cloud is the only way today to monitor the printer from remote this is quite important…

- [BUG] Please investigate and check all the problem we’re having with Slash after 3.14 firmware update like printing base sticking issues, z axis motor slipping (I have an open ticket for that) and the speed of the movement for first layers, eventually introducing a “super low” motor speed selectable for first layers…

- [BUG] Please make the model autorepair works. I’ve never been able to make it repair any models… Not a big problem as we are all using Meshmixer today for doing that. But if you have a feature that must work.

That said I like the software, it’s well done and functional. I only want to make some propositive suggestions that I hope could help you to improve the overall experience of using your printers.

If I’ll found something more I’ll adding it in this thread.