Hi Andy, Thanks for sharing such experience.

For printing big object, like you said, it need bigger strength to peel object from vat film. User can edit motor speed and raise height to get better printing result. For example, the land in below picture is a big object, we can set motor speed to “Low” and Raise height to “15mm”. By this way, the arm of printer will get bigger power to raise and peel object slowly. There also be enough time for liquid resin flowing to bottom of vat for second layer cure.

The advantage of UNIZ software is that user can set many parameters to adjust printing quality.

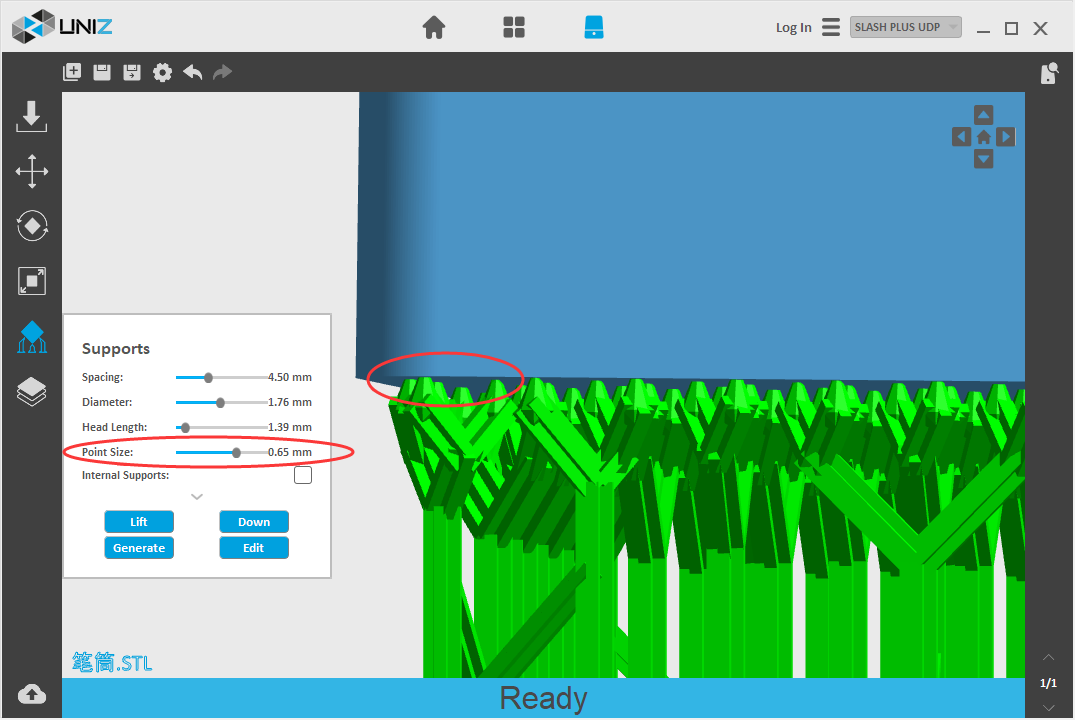

For object falling issue, user can increase “point size” of support. it will increase the size of contact area between support and object.