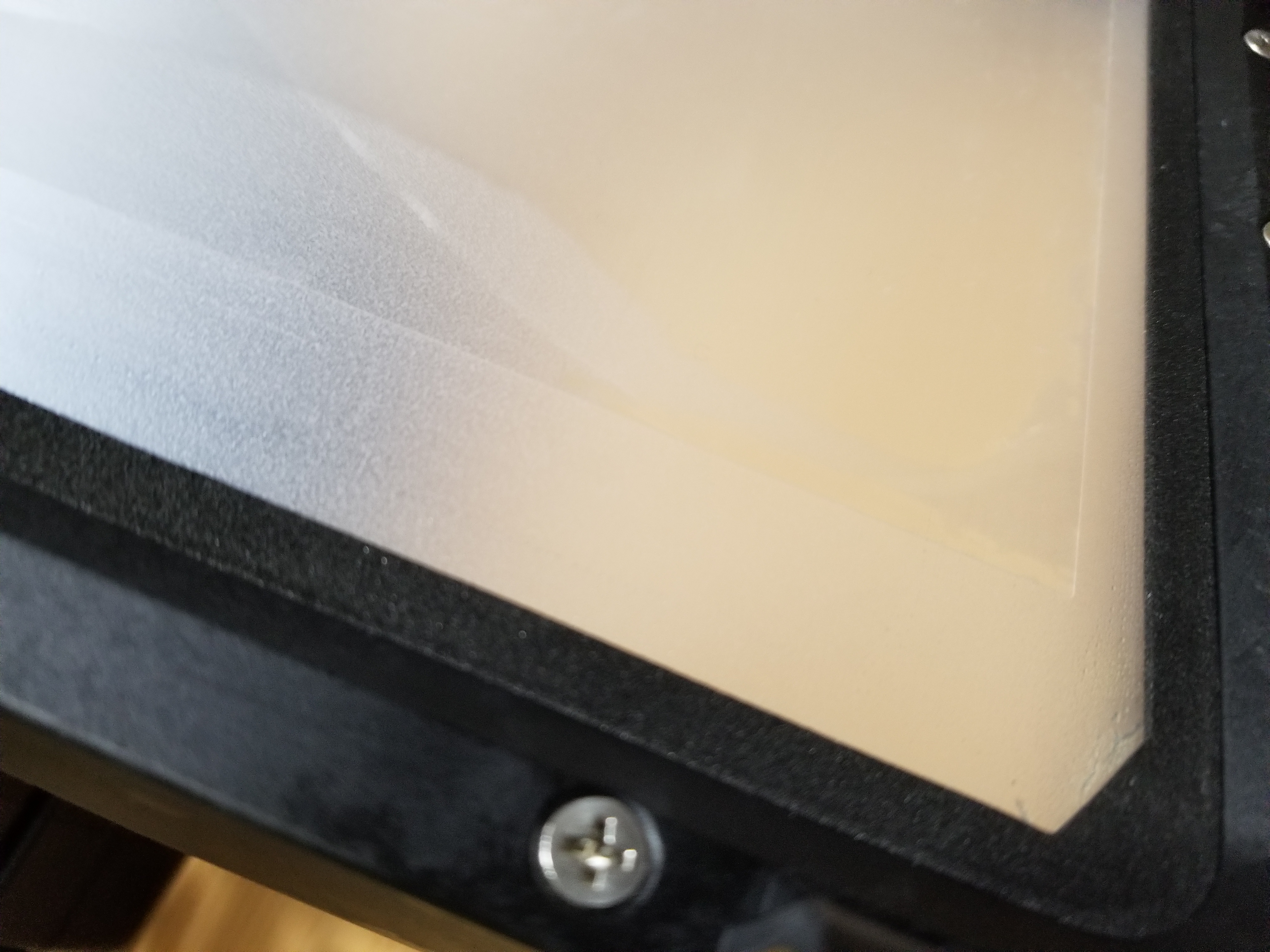

Just because this has been bugging me, I’ll go ahead and ask: is this secondary film supposed to be there underneath the vat film? Is it supposed to be on the bottom? Is it to protect the lcd?

This is not the lcd protective film, I removed that from the lcd when originally unboxing and setting up the unit.

Thanks!