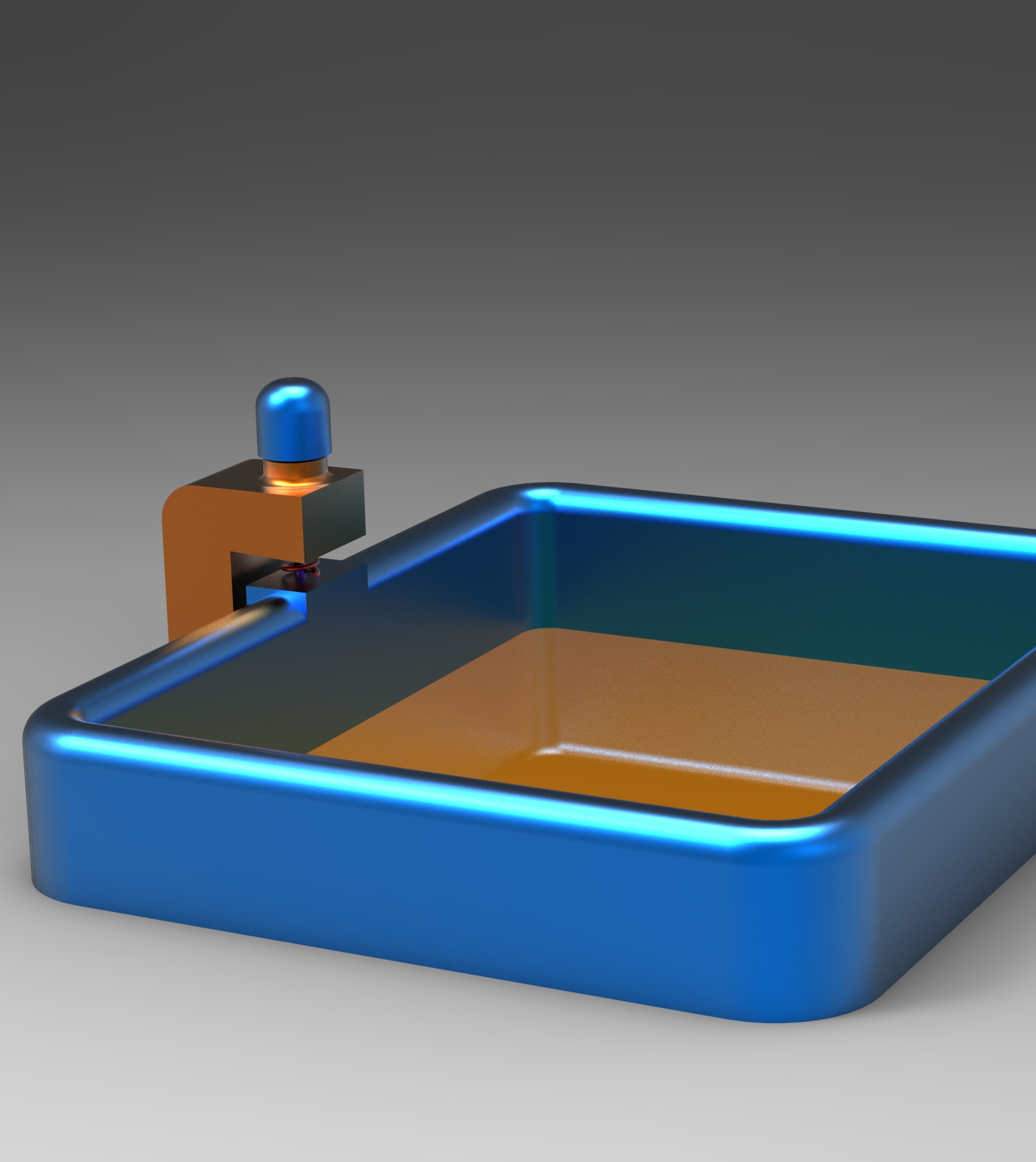

Peichao Wang I would like to propose an idea that I believe would make the separation from the Vat easier.

It is a mechanism composed of a spring (which can be registered more or less hardness).

Useful especially in the printing of large surfaces.

When the plate is lifted, drag the tray with it, at the same time the air penetrates under the Fep film, eliminating the vacuum effect between the LCD panel and the film.

The spring will then push the tray into the rest position